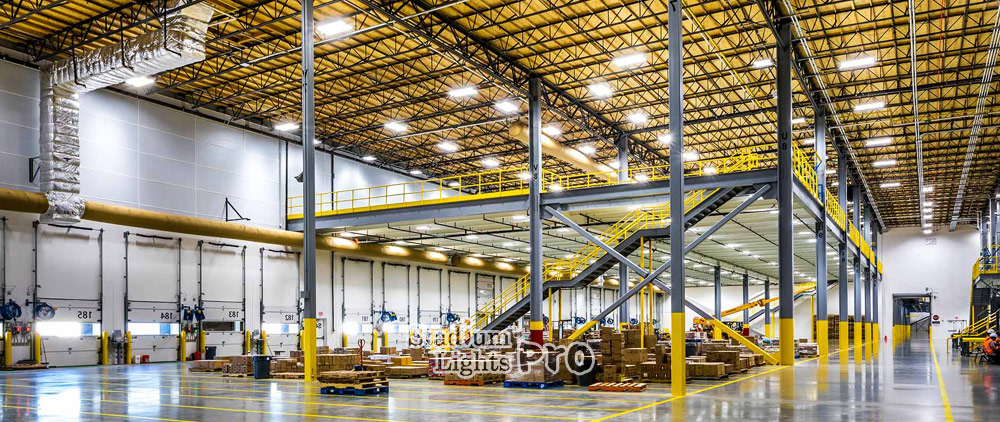

In the fast-paced world of modern logistics, distribution centers serve as critical hubs for storing, sorting, and shipping goods. To ensure the smooth operation of these centers, an often overlooked yet indispensable factor is lighting. Proper distribution center lighting not only enhances visibility and safety but also plays a vital role in overall operational efficiency. We will talk about the importance of lighting in distribution centers, how to select and install appropriate lighting, determining the quantity of lights required, and understanding the essential concept of lumens.

The importance of lighting in distribution centers

Effective distribution center lighting goes beyond mere illumination; it directly influences worker productivity, accuracy, and safety. Here are some key reasons why lighting should be a top priority.

Enhanced visibility

Clear and consistent lighting helps employees easily identify labels, barcodes, and product details, reducing picking errors and delays.

Safety and security

Adequate lighting minimizes the risk of accidents, such as collisions between vehicles and pedestrians or slips and falls due to obscured obstacles.

Productivity boost

Well-lit environments contribute to better employee morale and focus, leading to increased efficiency in tasks like packing, sorting, and shipping.

Accuracy and quality control

Adequate lighting assists in quality control checks, ensuring products meet the required standards before distribution.

Buying and installing lights: Considerations

When selecting lighting for your distribution center, several factors should be taken into account.

Lighting type

LED (Light Emitting Diode) lighting is the preferred choice due to its energy efficiency, longer lifespan, and reduced maintenance needs compared to traditional fluorescent or incandescent options.

Lighting placement

Proper placement of lights is crucial to avoid shadows, glare, and uneven coverage. A combination of overhead, task, and ambient lighting ensures comprehensive coverage.

Lighting controls

Implementing lighting controls such as motion sensors and dimmers can further optimize energy consumption by activating lights only when needed.

Maintenance considerations

Opt for fixtures with easily replaceable parts and consider the accessibility of fixtures for maintenance purposes.

What lights are used in distribution center?

Various types of lights are used in distribution centers to provide efficient and effective illumination for different areas and tasks. Here are some common types of lights used in distribution centers.

1. High-bay lights

High-bay lights are a specialized type of lighting designed to address the unique challenges posed by areas with high ceilings, such as storage sections within distribution centers. These lights are carefully engineered to emit focused and intense illumination that effectively reaches the floor from elevated heights. The term “high-bay” refers to the vertical clearance of space between the floor and the ceiling.

In distribution centers, storage sections often have considerable vertical clearance to accommodate stacked inventory or equipment. These areas require lighting solutions that can overcome the challenges of the increased distance between the light source and the work surface. Here’s a more detailed breakdown of their characteristics.

High ceilings and vertical spaces

High-bay lights are tailor-made for environments where the ceiling height is typically 15 feet (4.5 meters) or higher. These lights are capable of delivering sufficient light intensity to the ground despite the greater height.

Focused illumination

High-bay lights use advanced optics and design to direct light downwards with precision. This focused illumination minimizes light loss and ensures that the majority of the emitted light reaches the intended area, reducing wastage.

Lumen outputs

High-bay lights come in a range of lumen outputs, which determine the brightness and intensity of the light they emit. This variability allows distribution center managers to select the appropriate lumen output based on the tasks being performed and the required lighting levels.

Beam angles

The beam angle of a high-bay light refers to the spread of light it produces. Different areas within a distribution center may require different beam angles to achieve uniform coverage. For instance, narrow beam angles may be suitable for aisle lighting, while wider angles are preferable for open spaces.

Even coverage

To ensure consistent brightness across the distribution center’s vertical space, high-bay lights are strategically positioned to provide even coverage. This uniform lighting reduces shadows and ensures that employees can work efficiently and safely.

Options for efficiency

High-bay lights are available in energy-efficient LED variants, which offer long lifespans, reduced energy consumption, and minimal maintenance needs compared to traditional lighting technologies like metal halide or fluorescent lights.

Customization

Distribution centers can customize high-bay lighting solutions based on the specific layout and requirements of their storage sections. This may involve choosing different lumen outputs, beam angles, and mounting options.

2. Low-bay lights

Low-bay lights are a specialized type of lighting designed to illuminate areas with lower ceiling heights, typically ranging from 8 to 15 feet (2.4 to 4.5 meters). These lights are particularly well-suited for tasks that require close-up work, such as packing, sorting, and assembly, where detailed visual accuracy is essential.

3. Flood lights

Flood lights are a specialized category of lighting fixtures designed to provide broad and intense illumination across large outdoor spaces. They play a crucial role in enhancing visibility and safety in areas such as outdoor yards, loading docks, parking lots, and along the perimeter of distribution centers. Here’s a more detailed breakdown of their characteristics and applications.

Outdoor illumination

Flood lights are primarily used in outdoor areas where strong and expansive illumination is required. Their purpose extends beyond merely lighting up a space; they ensure that the surrounding environment is well-lit for various tasks and activities, even in dark or low-light conditions.

Loading docks

Flood lights are often installed at loading docks to illuminate the area where trucks are loaded and unloaded. These lights enable workers to perform their tasks safely and accurately, regardless of the time of day or prevailing weather conditions.

Wide beam angle

One of the defining features of flood lights is their ability to emit a wide and expansive beam of light. This broad coverage is essential for evenly lighting large horizontal areas, minimizing dark spots, and ensuring consistent visibility.

Perimeter lighting

Flood lights are strategically positioned along the perimeter of a distribution center to enhance security by deterring unauthorized access and providing clear visibility for surveillance cameras. Well-lit perimeters create a safer environment and discourage potential intruders.

Nighttime operations

In distribution centers that operate around the clock, flood lights are vital for maintaining efficient operations during nighttime shifts. They eliminate the challenges posed by limited natural light, allowing workers to perform tasks with ease and accuracy.

Weather resistance

Flood lights designed for outdoor use are constructed to withstand various weather conditions, including rain, snow, and extreme temperatures. Their durability ensures consistent performance regardless of environmental challenges.

Mounting options

Flood lights can be mounted on poles, walls, or structures, depending on the specific area being illuminated. The flexibility in mounting options allows for optimal placement that maximizes lighting effectiveness.

4. Task lights

Task lights are directed at specific workstations or areas where detailed tasks are performed. These lights ensure adequate visibility for tasks that require precision, such as quality control checks or paperwork.

5. Linear lights

Linear LED fixtures are often used in aisles, corridors, and pathways. They provide consistent and uniform lighting along linear paths and are designed to fit seamlessly into the layout.

6. Emergency lights

Emergency lighting is crucial in distribution centers to provide illumination in case of power outages or emergencies. These lights ensure safe evacuation routes and comply with safety regulations.

7. Motion sensor lights

Motion sensor lights are equipped with sensors that detect movement. They automatically turn on when motion is detected and turn off when no activity is sensed. These lights are used in areas with infrequent traffic to save energy.

8. Dimmable lights

Dimmable LED lights offer adjustable light output, allowing distribution centers to customize lighting levels based on the time of day or specific tasks. Dimming can help conserve energy and extend the life of the lights.

9. Lighting controls

Advanced lighting control systems, such as those integrated with building management systems, allow for centralized monitoring and adjustment of lighting levels across the distribution center. These systems enhance energy efficiency and streamline operations.

10. Exterior lighting

Exterior lighting, including pole lights and wall-mounted fixtures, illuminate the outside of the distribution center, providing a safe environment for vehicle traffic and enhancing security.

The choice of lighting type depends on the distribution center’s layout, ceiling height, tasks performed, and energy efficiency goals. A well-designed lighting plan combines various types of lights strategically to create an environment that ensures safety, efficiency, and optimal working conditions.

How many lights do we need to light a distribution center?

Let’s walk through an example calculation for estimating the number of LED lights needed to light a distribution center. For this example, we’ll assume the following,

- Distribution center area: 10,000 square feet

- Desired illumination levels:

- Storage areas: 50 lumens per square foot

- Picking areas: 100 lumens per square foot

- LED light lumen output: 5,000 lumens per fixture

- Ceiling height: 20 feet

Step 1 – Calculate total lumens needed in the distribution center

For storage areas:

Total lumens

= Area × Lumens per square foot

= 10,000 sq. ft × 50 lumens/sq. ft

= 500,000 lumens

For picking areas:

Total lumens

= Area × Lumens per square foot

= 10,000 sq. ft × 100 lumens/sq. ft

= 1,000,000 lumens

Step 2 – Determine number of LED lights

Number of lights = Total lumens needed ÷ Lumen output per fixture

For storage areas:

Number of lights

= 500,000 lumens ÷ 5,000 lumens/fixture

= 100 fixtures

For picking areas:

Number of lights

= 1,000,000 lumens ÷ 5,000 lumens/fixture

= 200 fixtures

Step 3 – Adjust for ceiling height

Since the ceiling height is 20 feet, high-bay LED fixtures might be needed for adequate coverage. Let’s assume a high-bay fixture has a lumen output of 20,000 lumens.

For storage areas:

Number of high-bay lights

= Total lumens needed ÷ Lumen output per high-bay fixture

= 500,000 lumens ÷ 20,000 lumens/fixture

= 25 fixtures

For picking areas:

Number of high-bay lights

= 1,000,000 lumens ÷ 20,000 lumens/fixture

= 50 fixtures

Step 4 – Total number of LED lights

Total number of LED lights

= Number of high-bay lights (Storage) + Number of high-bay lights (Picking)

= 25 fixtures (Storage) + 50 fixtures (Picking)

= 75 fixtures

Cost of LED high bay lights in a distribution center

Assuming that each high-bay fixture, with a lumen output of 20,000 lumens, is priced at approximately $80, the total cost for illuminating the distribution center can be calculated by multiplying the cost per fixture by the total number of fixtures needed. In this case, the calculation would be as follows.

Total cost

= Cost per fixture × Number of fixtures

= $80/fixture × 75 fixtures

= $6,000

The estimated total cost for buying and installing the required 75 high-bay lighting fixtures would be approximately $6,000 in the distribution center.

What is the reason for utilizing LED lights within a distribution center?

Energy efficiency

LED lights are highly energy-efficient, consuming significantly less electricity compared to traditional lighting options like fluorescent or incandescent bulbs. This efficiency translates to reduced energy costs, contributing to overall operational savings.

Long lifespan

LED lights have an exceptionally long lifespan, often lasting tens of thousands of hours. This longevity not only reduces the frequency of replacements but also minimizes maintenance costs and disruptions to normal operations.

Durability and reliability

LED lights are solid-state lighting solutions, meaning they lack fragile components like filaments or glass bulbs. This makes them highly resistant to shock, vibrations, and impact, making them well-suited for the dynamic environment of a distribution center.

Instant on/off

LED lights achieve full brightness instantly upon activation, unlike some other lighting technologies that require warm-up time. This feature is crucial in distribution centers where immediate illumination is needed to ensure safety and productivity.

Directional lighting

LEDs emit light in a specific direction, making them inherently more efficient in terms of light distribution. This characteristic minimizes the need for reflectors and diffusers, further increasing their efficiency.

Dimmability and controls

Many LED lights are compatible with dimming systems and advanced lighting controls, allowing for dynamic adjustment of light levels based on needs, occupancy, or time of day. This capability enhances energy savings and customization of lighting scenarios.

Color temperature options

LED lights are available in various color temperatures, allowing distribution center managers to select lighting that suits the specific tasks and ambiance required in different areas of the facility.

Reduced heat emission

LED lights emit very little heat compared to traditional bulbs, which can help maintain a more comfortable working environment within the distribution center. It also reduces the strain on cooling systems.

Environmental benefits

LED lights contain no hazardous materials like mercury, which is present in fluorescent lights. Moreover, their reduced energy consumption contributes to lower greenhouse gas emissions, aligning with sustainability goals.

Flexibility in design

LED lights come in various shapes, sizes, and designs, making them versatile for different lighting applications within the distribution center, from high-bay lighting in storage areas to task lighting at workstations.

Rapid technological advancements

The LED lighting industry has been experiencing rapid advancements in technology, leading to improvements in efficiency, color rendering, and even smarter lighting solutions that can integrate with building management systems.

Determining quantity of lights

The number of lights required depends on the size, layout, and purpose of the distribution center. A lighting professional can provide a more accurate assessment, but generally, a few guidelines apply,

Lighting intensity

Measure the illuminance required in different areas. For example, picking areas might need higher intensity lighting compared to storage zones.

Lighting uniformity

Aim for consistent lighting levels across the space to avoid stark contrasts that could strain employees’ eyes.

Ceiling height

Taller ceilings might require more powerful lighting solutions to effectively reach the ground.

Understanding lumens

Lumens are a unit of measurement that quantifies the total amount of visible light emitted by a source. When selecting lighting for distribution centers, consider the balance between lumens and wattage. Higher lumens per watt indicate greater energy efficiency. The required lumens depend on the area’s intended use. For example,

- General storage areas: 50-100 lumens per square foot

- Picking areas: 100-150 lumens per square foot

- Loading docks: 75-150 lumens per square foot

Conclusion

Opting for LED lights within distribution centers is a pragmatic choice that reaps numerous benefits. LED lights’ efficiency, longevity, and adaptability significantly enhance operational effectiveness and safety. Their energy-saving capabilities, minimal maintenance needs, and reduced environmental impact make them a cost-effective and sustainable solution. Embracing LED lighting is a commitment to a well-lit, efficient, and environmentally-conscious distribution center, aligning with both business success and responsible practices.

For expert guidance in implementing an optimal lighting design tailored to your distribution center’s needs, we invite you to reach out to us. Avail of our complimentary lighting design consultation, and let us help illuminate the path to a more efficient and cost-effective distribution center lighting solution.